Feature and advantages:

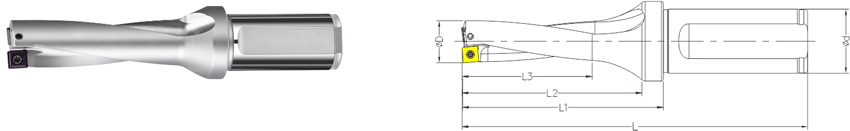

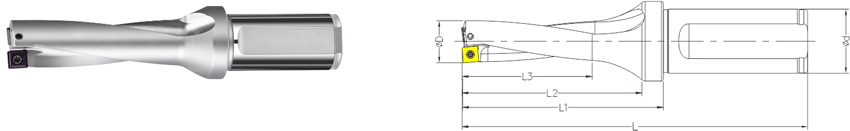

·The difference between U drill and ordinary drill is that U drill uses hard alloy blades and designs inner and outer edge blades. After the drill is worn, the blades can be replaced directly without regrinding.

·U drill has better rigidity and can use a high feed rate, Moreover, the processing diameter of U drill is much larger than that of ordinary drill. The drilling range can reach D10mn~80mm, and the longest processing depth can reach 5 times diameter

·The precision of the u-drill is higher than that of the conventional drill, and the finish is better, and the U-drill can correct the precision of the hole position.

·U drill can drill holes on surfaces with inclination angles less than 30r~ without reducing cutting parameters.

·When the cutting parameters of U drill are reduced by 30%, discontinuous cutting can be realized, such as processing intersecting hole, intersecting hole and phase perforation.

·U drill can realize drilling of multi-step holes, and can boring, chamfering and eccentric drilling.

·The drilling cuttings of U drill are mostly short cuttings, and the internal cooling system can be used for rapid chip removal without iron cuttings, which is conducive to product processing continuity, shorten processing time and improve efficiency.

·There is no need to pre-drill the center hole with U drill, and the bottom surface of the processed blind hole is relatively straight, eliminating the need for flat bottom drill bit.

·U drill machine is widely used, including computer gong machining center, CNC lathe, ordinary lathe, hole machining machinery, etc., which can greatly save processing time and cost for users.

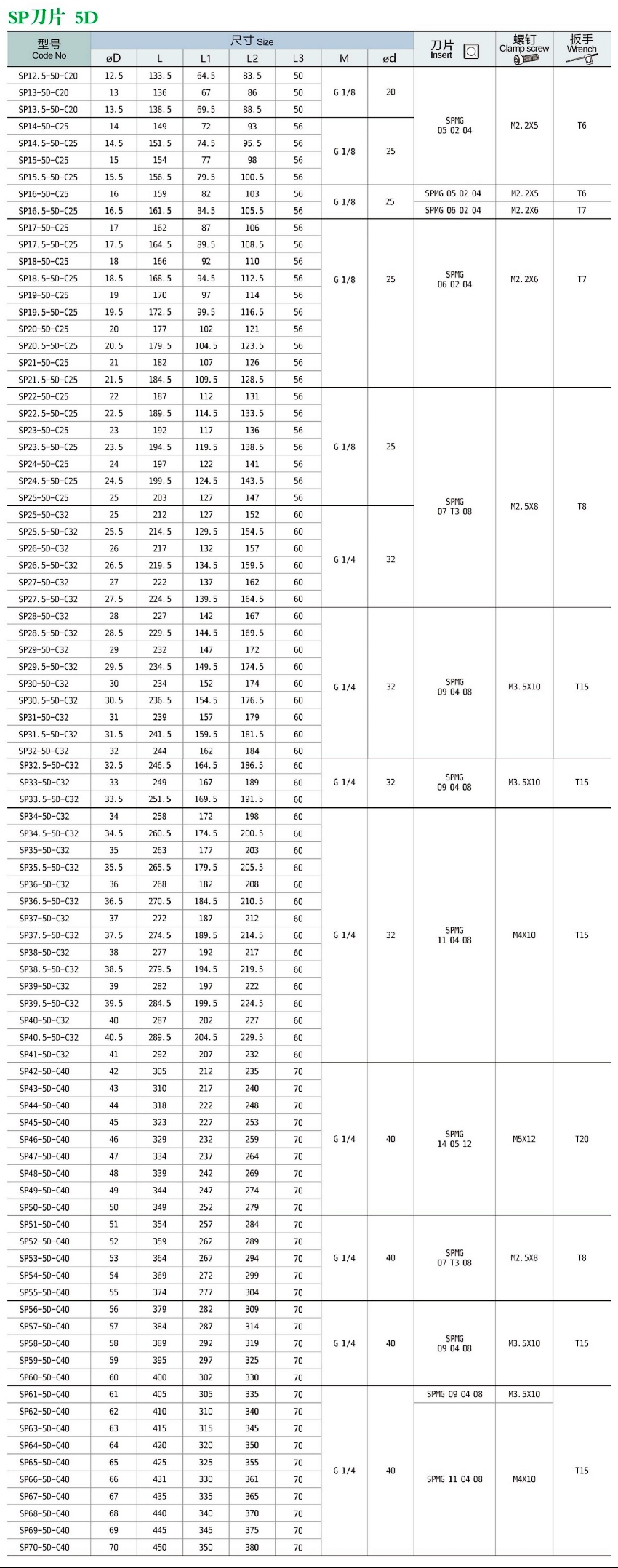

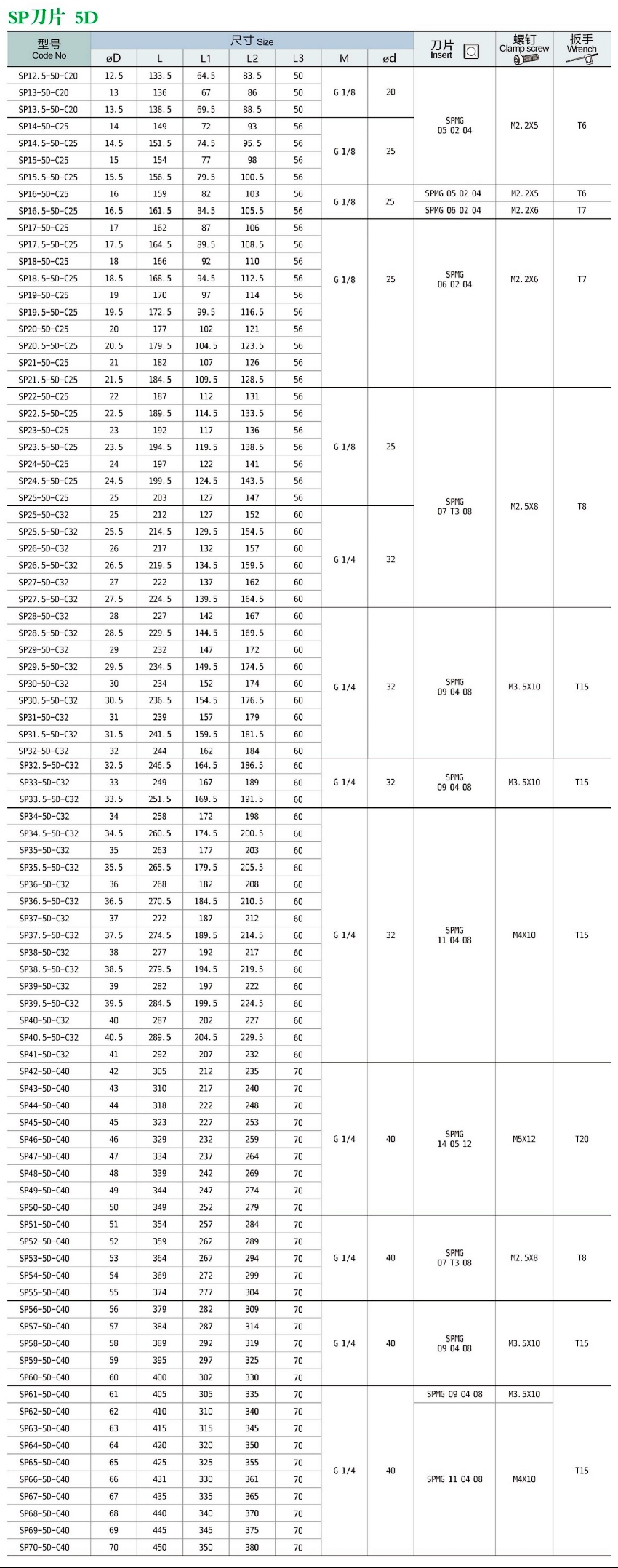

Specifications: